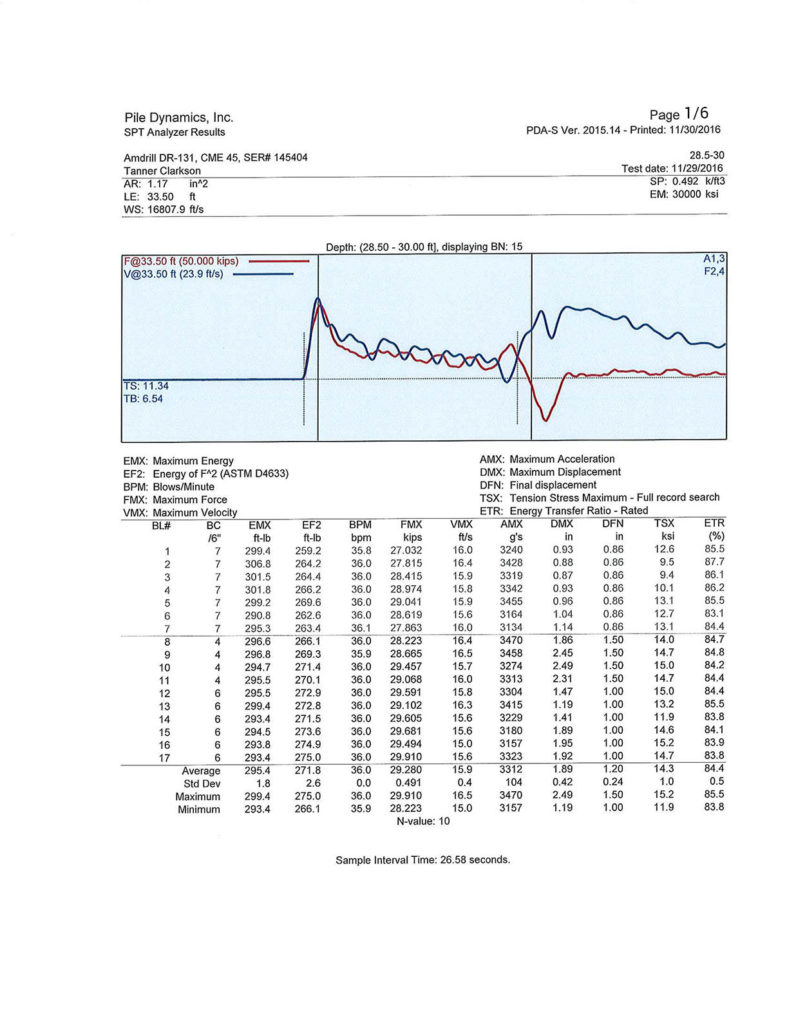

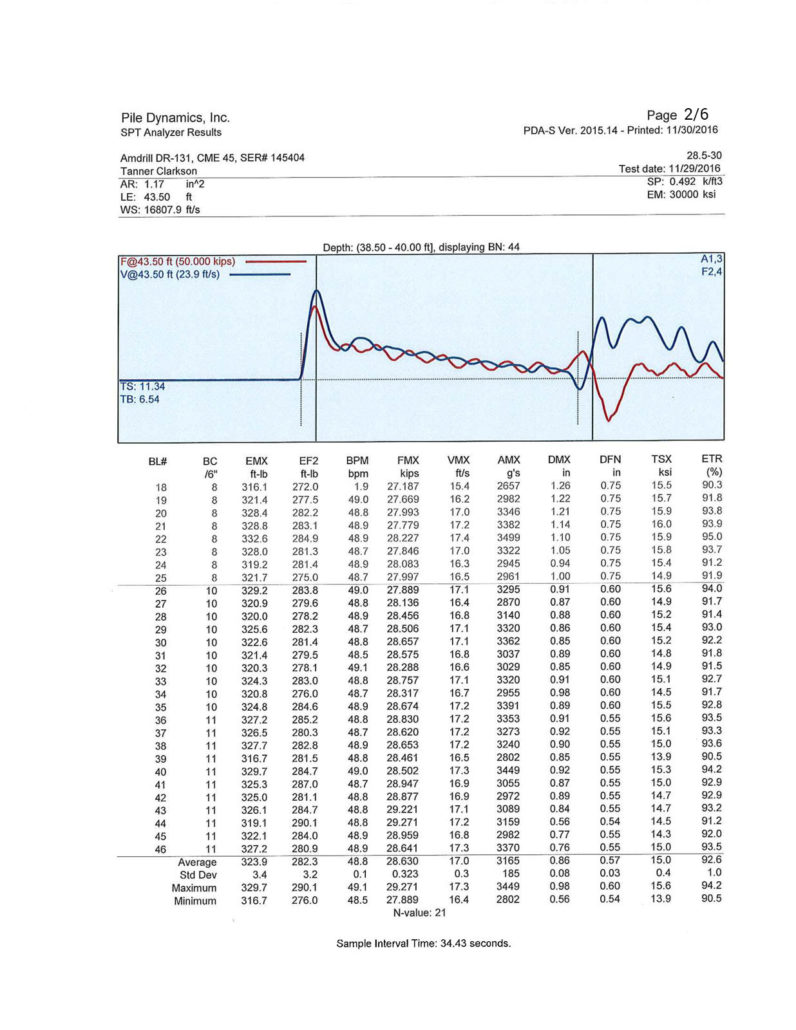

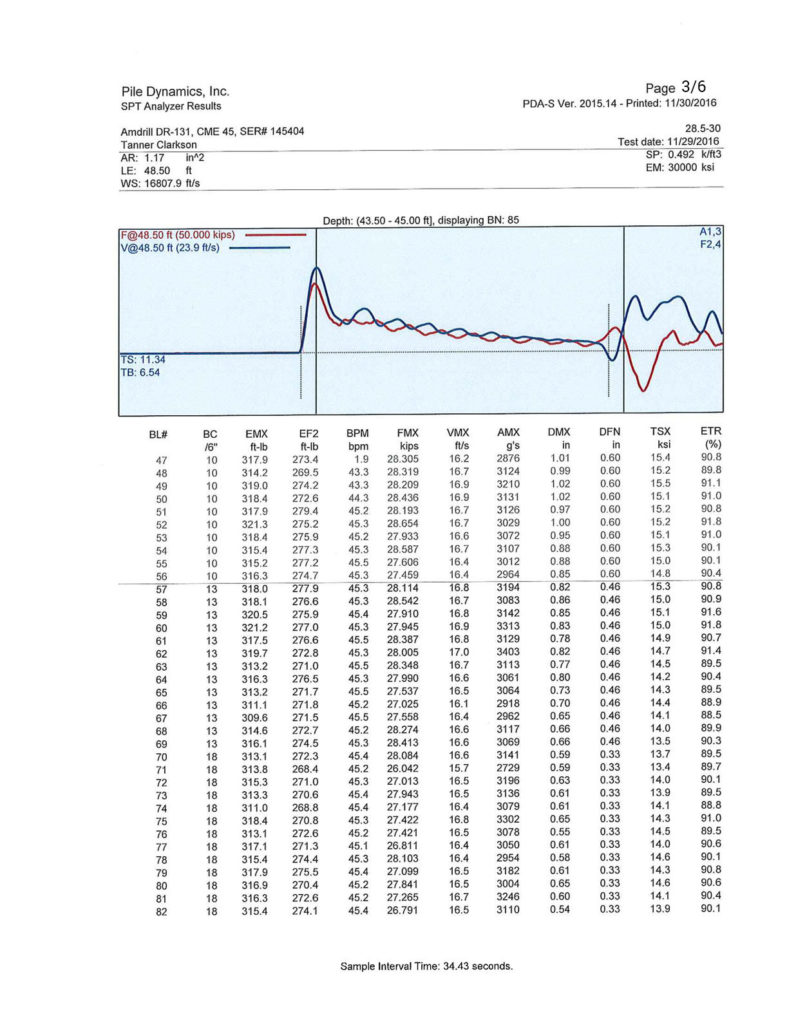

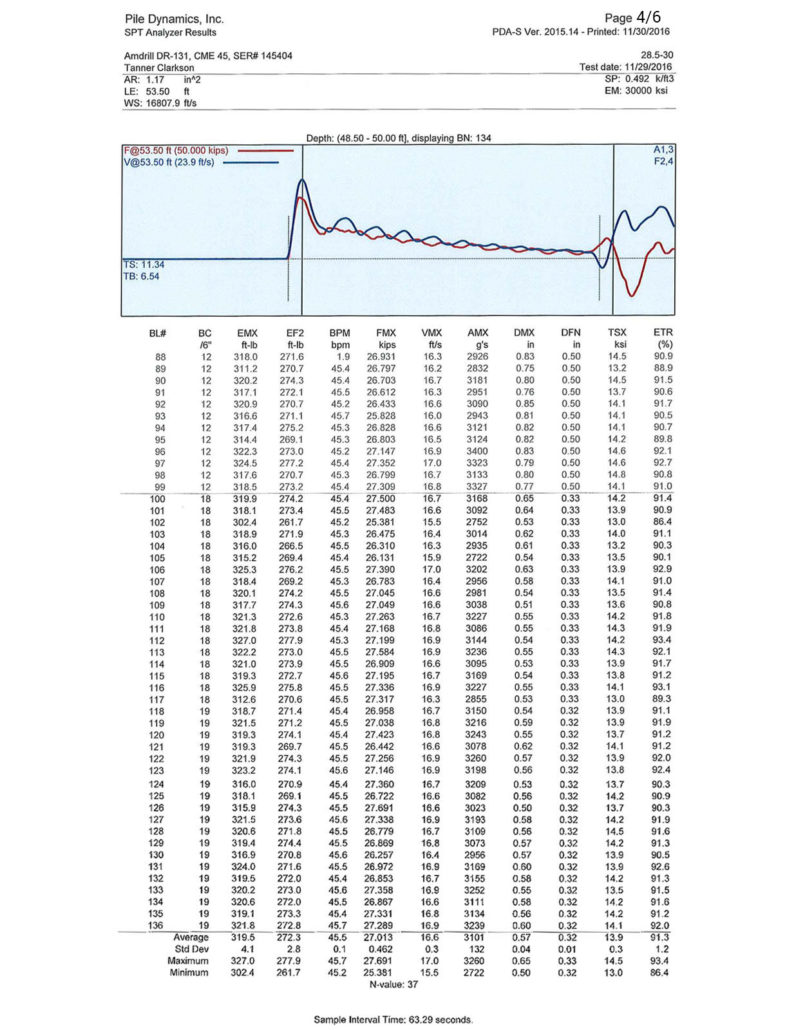

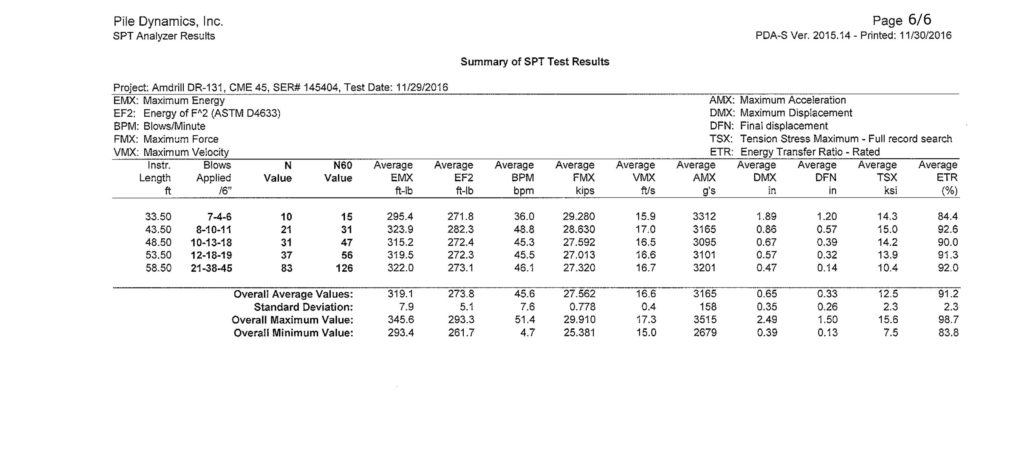

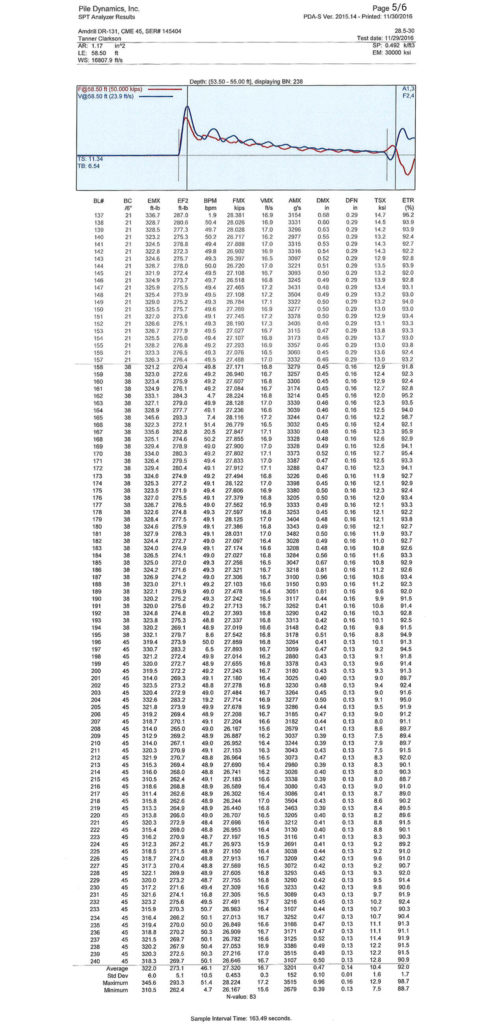

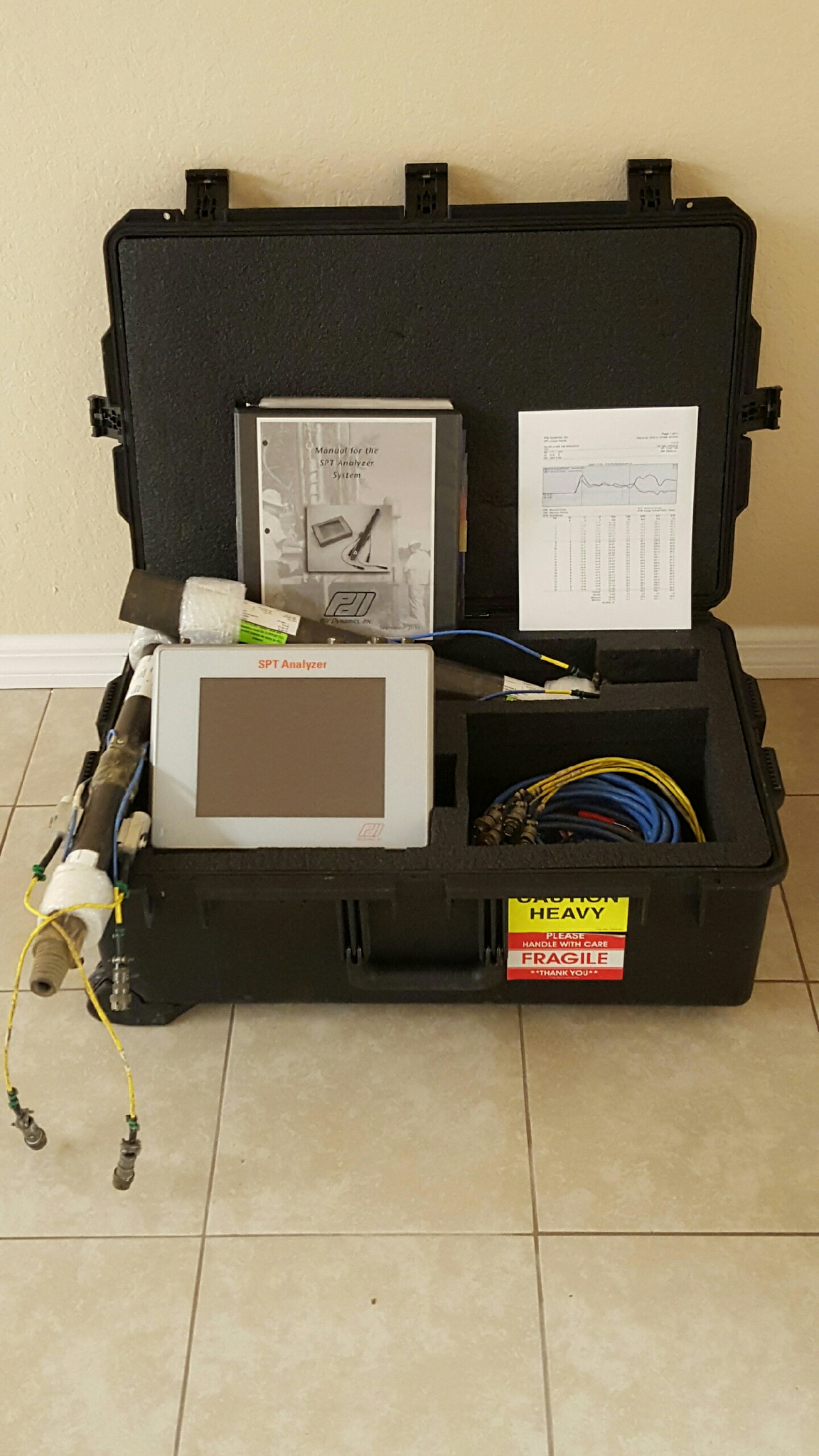

Amdrill owns one of the most modern and updated SPT Energy Analyzers for hammer calibrations in the field. The equipment processes the data collected and in several minutes provides the results without having to work the formulas out long hand. It is an advanced and yet simplified process that Amdrill is part of. The SPT Analyzer provides detailed information on the  equipment’s efficiency, which will be tagged to the equipment’s serial number; it measures (but is not limited to) the maximum force, velocity, energy, blows per minute and energy transfer ratio of the equipment.

equipment’s efficiency, which will be tagged to the equipment’s serial number; it measures (but is not limited to) the maximum force, velocity, energy, blows per minute and energy transfer ratio of the equipment.

*It should be noted that the hammer operator (driller if auto hammer/helper if safety hammer) should be paired with the equipment, for jobs requiring calibrated equipment. This is to avoid variances in human operations that could alter the equipments efficiencies.

Testing is done with 5 samples in accordance with ASTM standards and a certified operator. There must be 5 “good samples’ meaning, if the rods are loose and provide inadequate readings or a low N-Value is present, we must continue until we have 5 “good samples.” There are 4 standards and recommendations that are subjected to the drilling process and are asked to comply with before testing.

They are as listed:

-5 samples are recommended

-5’ centers are recommended

-30’ starting depth is recommended

-N-Value greater than 10 is required

The other standards and recommendations are built into the SPT Analyzer software leaving little room for human error.

The process normally adds about 10 minutes to the drilling process. The testing can be done at our yard: 19496 Fort Dade Ave, Brooksville, FL 34601 or out in the field at your jobsite/office. With the calibration results, you will receive a field worksheet, the raw computer data, and certification/calibration documents for the operator and equipment (SPT Analyzer, instrumented rod, and gauges). This will be a total of 5 PDFs and the raw data in a zipped file.

View Examples Below: